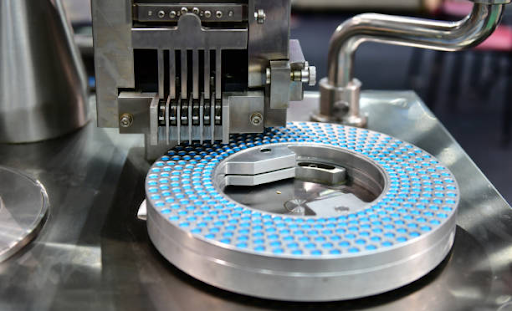

Mario Websters’ findings show that precision, efficiency, and reliability are virtues that must be practiced in the pharmaceutical industry. When it comes to capsule filling machines there is a lot to be done by choosing the right supplier so that the working process becomes smooth and efficient. Being that there are countless pharma machines manufacturers who offer different products, choosing the right capsule filling machine supplier is not an easy task. This article gives a useful guideline to make sure that a right supplier is selected and is capable of offering a better pharmaceutical solution in the long run.

Get to Know Your Pharmaceutical Needs

Of course, prior to comparing the suppliers, one has to know what exactly he or she is looking for when it comes to pharmaceuticals. Due to differences in needs resulting from production rates, capsule sizes, and products to be filled in each facility, every facility has its specific requirements. For example, a biotech coupled to develop and manufacture high-precision capsules for specialized medication will need dissimilar tools from a nutraceutical firm that deals with supplements.

It will also help you determine that suppliers provide machines that will address your needs hence the importance of defining your needs. The ideal capsule filling machine supplier should offer machines that can handle any size of the capsule, one that can adjust the volume of the filling and the material that is compatible with the capsules. Since suppliers know the various aspects of the industry of their client, they are in a position of telling them the various ways to increase efficiency and minimize costs. When certain on what one wants to produce, they will better know the type of suppliers to concentrate on that taps the right market segment. Furthermore, analyzing whether your future requirements will require greater bandwidth or additional features like scalability will help to know whether this or that piece of equipment will remain relevant later on.

Supplier Experience ERA

Experience and reputation of the supplier are some of the most important things that one needs to consider to arrive at the right decision. New pharma machines manufacturers are likely to provide substandard equipment and poor after-sale services as compared to reputable manufacturers. When selecting a capsule filling machine it is important to identify suppliers with rich experience in capsule filling machines design, manufacturing companies and those with regular maintenance programs.

Today there are some ways to assess the reputation of a supplier for example reading customers’ feedback and their case studies or asking for references. It is not difficult for any company to get testimonials or samples of work with other pharmaceutical organizations from many reputable suppliers. Selecting a supplier capable in this front means that he/she has the best equipment suitable for the job given that the company delivers service in line with the industry standards. While working with an experienced supplier, the buyer is also more likely to be aware of future changes in the industry and, therefore, to obtain equipment that complies with such changes. Furthermore, experience with global clients suggests that the supplier effectively maintains its delivery of goods.

Check for Compliance with Industry Standards

Purchasing a capsule filling machine can only be done from companies that meet the international industry standards. Pharmaceutical production is governed by quality, safety and hygiene requirements hence your equipment must be of the same standard. It is good to confirm whether the existing machines at the supplier’s premises are approved under regulation like ISO, CE or GMP to conform to pharmaceutical production standards.

Also ask the supplier about his manufacturing techniques and control mechanisms for the products. The leading manufacturers of pharma machines have to incorporate various tests and inspection procedures that would guarantee the machines’ smooth performance. A compliant machine does not only make it easier to meet all the set legal standards but also reduces dangers of product recall and maintains the public’s safety. It is also important for suppliers to be committed to compliance as they prove concern with offering progressive and safe solutions. Training compliant machines helps establishments show regulatory authorities, customers and the public that your business is militant against unnecessary risks and therefore will not be embarrassed by any embarrassing events. These standards should also embrace the supplier’s manufacturing plant and all other services offered after the sale.

Compare Pricing and Long-Term Value

Pricing is a crucial component; however, it should not be the only criteria you’ll assess. Of course, price is a key consideration, but it is always important to obtain value that will ensure the item is durable. Sometimes people think that buying cheaper machines would be better for their business but in the future they find out that they have spent much more on maintenance and sometimes these machines break down often and result in low productivity.

Get package quotes from different pharma machines manufacturers, so that you can compare what each supplier entails. They should include warranty, spare parts, and energy when comparing the total cost of ownership for the product. While a premium-quality machine costs a bit more initially, the long run benefits from good value for money as it reduces on downtime and duration before which the machine would require replacement. Do not rush to compare a one-time cost of the equipment and consider how the piece of equipment will help increase your production rate, diminish the length of downtimes, and, sometimes, lower the costs of maintenance. It is a far better option to decide on a supplier that is providing long-lasting and effective machines in your business since it will bring long term stability and cost reduction.

Conclusion

In selecting the best capsule filling machine supplier for your pharmaceutical needs you need to determine industry experience, standard compliance and the price. If you want the best capsule filling machine, choosing a reliable supplier that has a good track record can guarantee that you get the best equipment that can improve capsule filling further and can meet current regulations. The implication is that it is possible to source machinery for your business from credible pharma machines manufacturers in a bid to use machines that offer value to your pharmaceutical business for the long term. It is advisable to use a considerable amount of time to evaluate the possible suppliers so that a long-term mutual beneficial relationship can be developed. When you find the right partner, not only will your operational performance improve, but also set the stage for steady growth in the fast paced world of the pharmaceutical industry. Choosing a right partner for supply is a strategic policy decision that pays off by guaranteeing the quality of products, better productivity and compliance to the industrial standards.